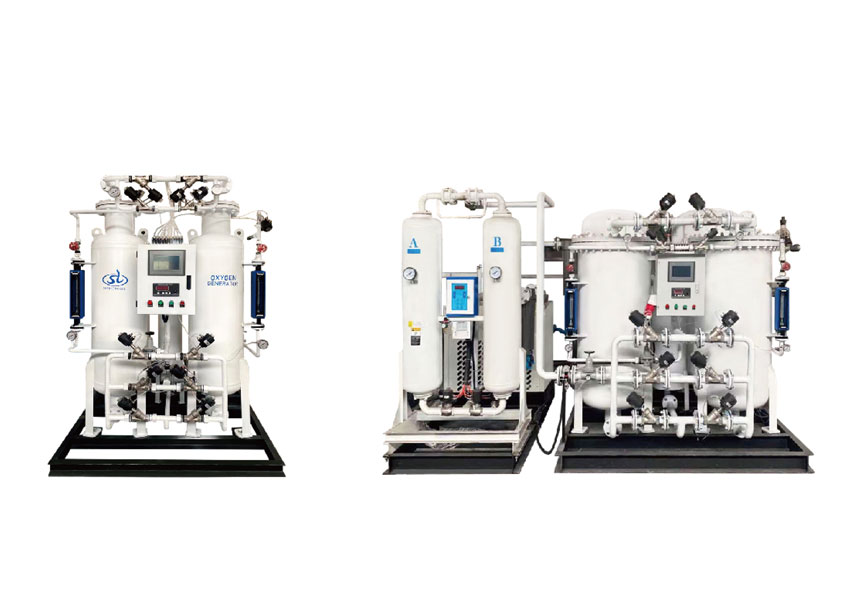

Working principle of medical oxygen generator:

According to the pressure swing adsorption principle, the use of zeolite molecular sieve as adsorbent, due to the characteristics of selective adsorption zeolite molecular sieve, nitrogen adsorption by zeolite molecular sieve, oxygen is enriched in the gas phase, nitrogen and oxygen separation under the action of pressure swing adsorption. The use of two adsorption tower process, a tower adsorption oxygen production, a tower desorption regeneration, through PLC intelligent program to control the opening and closing of pneumatic Angle seat valve, so that the two towers cycle alternating, continuous alternating, contin-uous oxygen output.

PSA oxygen generator is based on the pressure swing adsorption principle, the use of zeolite molecular sieve as adsorbent,under constant pressure, from the air to make oxygen. After purification and drying compressed air, pressure adsorption and decompression desorption are carried out in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the pores of zeolite molecular sieve is much higher than that of oxygen. Nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. After decompression to atmospheric pressure, adsor-bent desorbed nitrogen and other impurities, to achieve regeneration. In general, two adsorption towers are set up in the system, one tower adsorption oxygen production, the other - tower desorption regeneration, through the PLC program controller control pneumatic valve opening and closing, so that the two towers alternate circulation, in order to achieve the purpose of continuous production of oxygen.

Application areas:

Oxygen in hospital wards; Oxygen inhalation in ICU ward; Oxygen for high pressure oxygen chamber; Oxygen for operating room; Diffuse central oxygen supply.

Oxygen machine parameter selection:

| 制氧机型号 | 产氧量Nm3/h | 40L气瓶 每小时冲瓶数 | 50L气瓶 每小时冲瓶数 | 空压机选型 | 集装箱式 制氧机尺寸 | 额定功率 (含增压机空压机冷干机) |

| SLPO-10/93%+2 | 10 | 1.5 | 1 | 15KW | 20GP | 25KW |

| SLPO-20/93%+2 | 20 | 3 | 2 | 30KW | 20GP | 45KW |

| SLPO-30/93%+2 | 30 | 5 | 3 | 37KW | 20GP | 54KW |

| SLPO-40/93%+2 | 40 | 6.5 | 4 | 55KW | 40HP | 76KW |

| SLPO-50/93%+2 | 50 | 8 | 5 | 75KW | 40HP | 98KW |

| SLPO-60/93%+2 | 60 | 10 | 6 | 75KW | 40HP | 105KW |